Infrared Thermography

Inspeksi Termal untuk Deteksi Dini Masalah Kelistrikan dan Mekanikal

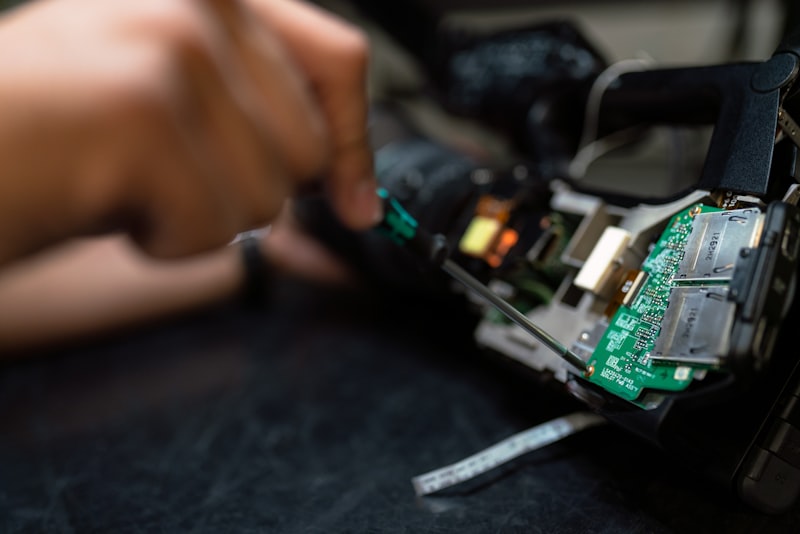

Infrared Thermography adalah metode inspeksi non-kontak menggunakan kamera inframerah untuk mendeteksi perbedaan suhu pada peralatan listrik dan mekanikal. Layanan ini digunakan untuk mengidentifikasi potensi gangguan sebelum berkembang menjadi kerusakan serius atau menyebabkan gangguan operasional.

Power Electric Utama menyediakan layanan Infrared Thermography sebagai bagian dari preventive maintenance untuk meningkatkan keandalan dan keselamatan sistem.

Lingkup Layanan Infrared Thermography

- Inspeksi Peralatan Kelistrikan

Pemeriksaan dilakukan pada panel listrik, sambungan kabel, breaker, busbar, dan komponen kelistrikan lainnya untuk mendeteksi hotspot atau ketidakwajaran suhu yang mengindikasikan koneksi longgar, beban berlebih, atau degradasi komponen.

- Inspeksi Peralatan Mekanikal

Infrared Thermography juga digunakan untuk memeriksa komponen mekanikal yang berputar atau bekerja secara kontinu, seperti bearing, motor, dan sistem transmisi, guna mengidentifikasi gesekan berlebih atau ketidakseimbangan panas.

- Deteksi Dini Potensi Gangguan

Perbedaan suhu yang terdeteksi dianalisis untuk mengidentifikasi potensi kegagalan sebelum terjadi kerusakan atau downtime. Pendekatan ini membantu mencegah gangguan mendadak pada sistem.

- Inspeksi Tanpa Menghentikan Operasional

Pemeriksaan dilakukan tanpa kontak langsung dan tanpa harus mematikan peralatan, sehingga inspeksi dapat dilakukan saat sistem beroperasi normal.

- Analisis dan Interpretasi Hasil Termal

Hasil pengukuran suhu dianalisis oleh tenaga teknis berpengalaman untuk menentukan tingkat keparahan dan rekomendasi tindak lanjut yang diperlukan.

Manfaat Infrared Thermography

- Mengurangi risiko gangguan dan kegagalan peralatan

- Mendukung program preventive maintenance

- Meningkatkan keselamatan operasional

- Mengoptimalkan kinerja sistem kelistrikan dan mekanikal

- Membantu perencanaan perbaikan yang lebih efektif

Aplikasi Infrared Thermography

Layanan ini dapat diterapkan pada:

- Panel distribusi listrik

- Gardu dan sistem kelistrikan

- Peralatan industri dan fasilitas produksi

- Gedung komersial dan infrastruktur

Tentang Power Electric Utama

Power Electric Utama adalah penyedia layanan kelistrikan dan inspeksi teknis yang berfokus pada peningkatan keandalan dan keselamatan sistem. Dengan metode kerja profesional dan dukungan teknis yang terukur, kami membantu pelanggan mendeteksi dan mencegah potensi masalah sejak dini.

Hubungi Kami

Untuk layanan Infrared Thermography, silakan hubungi Power Electric Utama untuk konsultasi dan penjadwalan inspeksi sesuai kebutuhan operasional Anda.

Infrared Thermography

Thermal Inspection for Early Detection of Electrical and Mechanical Issues

Infrared Thermography is a non-contact inspection method using infrared cameras to capture temperature profiles on electrical and mechanical equipment. By reading heat differences accurately, this service helps identify potential disturbances long before they escalate into serious damage or unexpected shutdowns. The method is widely used to evaluate equipment condition while strengthening system reliability and operational safety.

Power Electric Utama provides Infrared Thermography as an essential part of preventive maintenance programs. With a practical and field-focused approach, we help industrial and commercial facilities understand the real thermal behavior of their assets so daily operations remain stable and reliable.

Scope of Infrared Thermography Services

Electrical Equipment Inspection

Thermal checks are carried out on distribution panels, cable connections, breakers, busbars, and other electrical components to detect hotspots or abnormal temperature rises. These conditions often indicate loose joints, overload, or gradual component degradation. Early identification allows maintenance teams to plan precise corrective actions without waiting for failures to occur.

Mechanical Equipment Inspection

The method is also applied to continuously running mechanical parts such such as bearings, motors, and transmission systems. Abnormal heat patterns on rotating components may suggest excessive friction or thermal imbalance. This insight helps protect mechanical systems that directly support electrical performance.

Early Detection of Potential Disturbances

Temperature differences captured during inspection are analyzed to map possible failure points before real damage or downtime happens. This preventive approach reduces the risk of sudden interruptions and supports better asset management planning.

Inspection Without Stopping Operations

Because Infrared Thermography is fully non-contact, inspections can be performed while equipment operates normally and without switching off power. This makes the service safe, efficient, and practical for facilities with tight operational schedules.

Thermal Result Analysis and Interpretation

All measurements are reviewed by experienced technical personnel to determine severity levels and follow-up recommendations. Customers receive clear guidance on which sections require immediate attention and which can be handled through scheduled maintenance.

Benefits of Infrared Thermography

- Reduces the risk of equipment disturbances and failures

- Strengthens preventive maintenance programs

- Improves workplace safety

- Optimizes electrical and mechanical performance

- Supports more accurate repair planning

- Extends equipment service life

Applications

This service can be implemented on:

- Electrical distribution panels

- Substations and medium voltage networks

- Industrial equipment in production facilities

- Commercial buildings and utilities

- Infrastructure and public service installations

Power Electric Utama

Power Electric Utama focuses on electrical services and technical inspections aimed at strengthening reliability and safety of power systems. Through standardized methods and practical technical support, we help customers detect and prevent potential problems at an early stage so their operations remain secure, efficient, and well planned.

Contact

For Infrared Thermography services, feel free to reach out to Power Electric Utama for consultation and scheduling that fits your operational needs. Our team will be happy to discuss how thermal inspection can help keep your equipment safe and reliable.